Encoder Renishaw Vionic - Test Bench

Table of Contents

This report is also available as a pdf.

You can find below the documentation of:

In this document, we wish to characterize the performances of the encoder measurement system. In particular, we would like to measure:

- the measurement noise

- the linearity of the sensor

- the bandwidth of the sensor

This document is structured as follow:

- Section 1: the expected performance of the Vionic encoder system are described

- Section 2: a simple model of the encoder is developed

- Section 3: the noise of the encoder is measured and a model of the noise is identified

- Section 4: the linearity of the sensor is estimated

1 Expected Performances

The Vionic encoder is shown in Figure 1.

Figure 1: Picture of the Vionic Encoder

From the Renishaw website:

The VIONiC encoder features the third generation of Renishaw’s unique filtering optics that average the contributions from many scale periods and effectively filter out non-periodic features such as dirt. The nominally square-wave scale pattern is also filtered to leave a pure sinusoidal fringe field at the detector. Here, a multiple finger structure is employed, fine enough to produce photocurrents in the form of four symmetrically phased signals. These are combined to remove DC components and produce sine and cosine signal outputs with high spectral purity and low offset while maintaining bandwidth to beyond 500 kHz.

Fully integrated advanced dynamic signal conditioning, Auto Gain , Auto Balance and Auto Offset Controls combine to ensure ultra-low Sub-Divisional Error (SDE) of typically \(<\pm 15\, nm\).

This evolution of filtering optics, combined with carefully-selected electronics, provide incremental signals with wide bandwidth achieving a maximum speed of 12 m/s with the lowest positional jitter (noise) of any encoder in its class. Interpolation is within the readhead, with fine resolution versions being further augmented by additional noise-reducing electronics to achieve jitter of just 1.6 nm RMS.

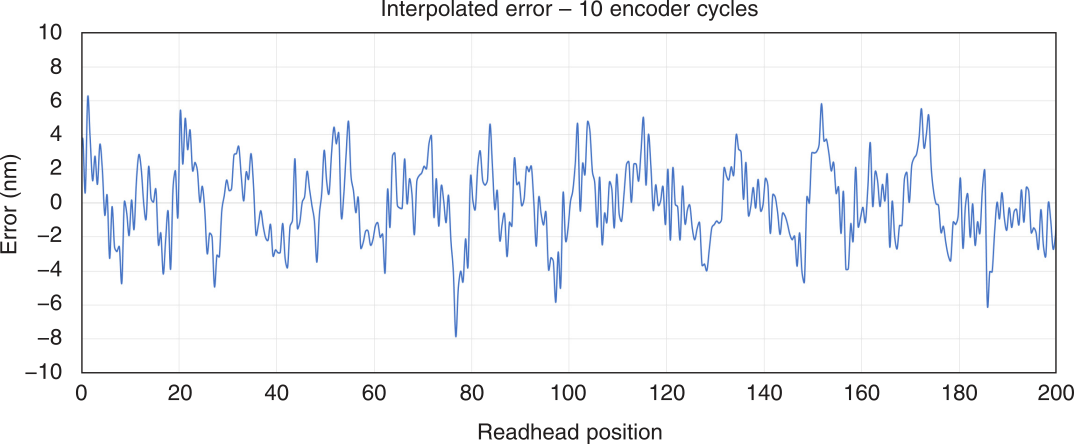

The expected interpolation errors (non-linearity) is shown in Figure 2.

Figure 2: Expected interpolation errors for the Vionic Encoder

The characteristics as advertise in the manual as well as our specifications are shown in Table 1.

| Characteristics | Manual | Specification |

|---|---|---|

| Time Delay | < 10 ns | < 0.5 ms |

| Bandwidth | > 500 kHz | > 5 kHz |

| Noise | < 1.6 nm rms | < 50 nm rms |

| Linearity | < +/- 15 nm | |

| Range | Ruler length | > 200 um |

2 Encoder Model

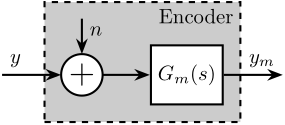

The Encoder is characterized by its dynamics \(G_m(s)\) from the “true” displacement \(y\) to measured displacement \(y_m\). Ideally, this dynamics is constant over a wide frequency band with very small phase drop.

It is also characterized by its measurement noise \(n\) that can be described by its Power Spectral Density (PSD) \(\Gamma_n(\omega)\).

The model of the encoder is shown in Figure 3.

Figure 3: Model of the Encoder

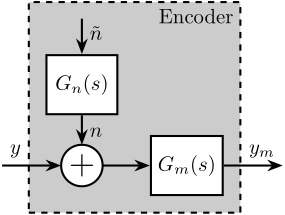

We can also use a transfer function \(G_n(s)\) to shape a noise \(\tilde{n}\) with unity ASD as shown in Figure 2.

3 Noise Measurement

This part is structured as follow:

- Section 3.1: the measurement bench is described

- Section 3.2: long measurement is performed to estimate the low frequency drifts in the measurement

- Section 3.3: high frequency measurements are performed to estimate the high frequency noise

- Section 3.4: the Spectral density of the measurement noise is estimated

- Section 3.5: finally, the measured noise is modeled

3.1 Test Bench

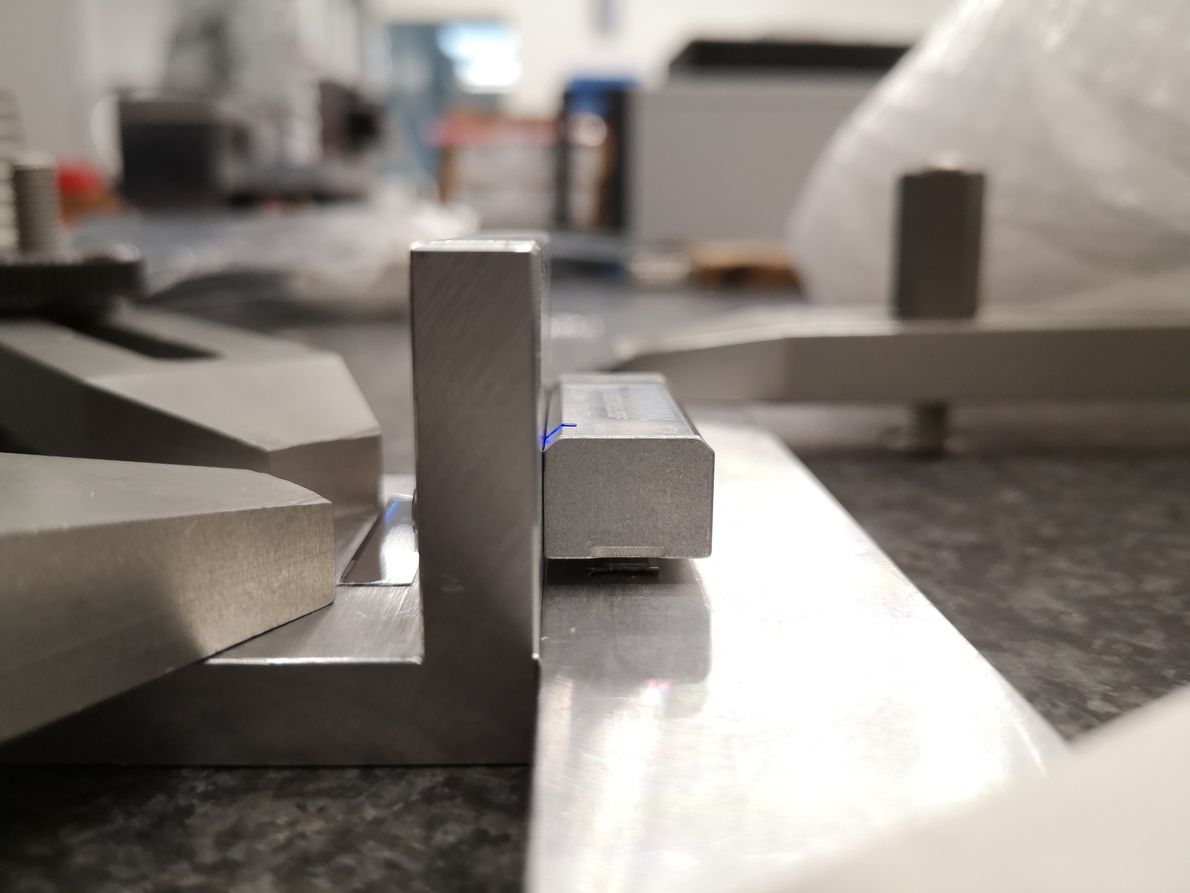

To measure the noise \(n\) of the encoder, one can rigidly fix the head and the ruler together such that no motion should be measured. Then, the measured signal \(y_m\) corresponds to the noise \(n\).

The measurement bench is shown in Figures 5 and 6. Note that the bench is then covered with a “plastic bubble sheet” in order to keep disturbances as small as possible.

Figure 5: Top view picture of the measurement bench

Figure 6: Side view picture of the measurement bench

3.2 Thermal drifts

Measured displacement were recording during approximately 40 hours with a sample frequency of 100Hz. A first order low pass filter with a corner frequency of 1Hz

enc_l = load('mat/noise_meas_40h_100Hz_1.mat', 't', 'x');

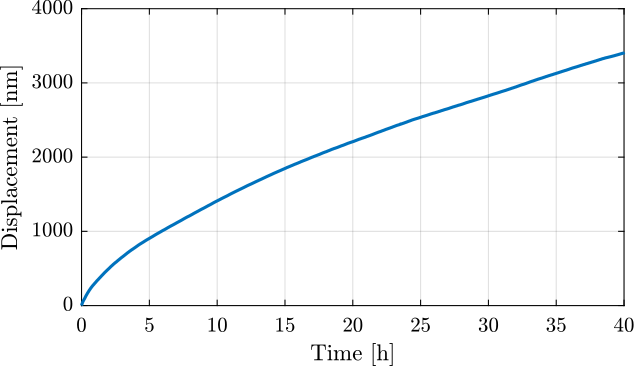

The measured time domain data are shown in Figure 7.

Figure 7: Measured thermal drifts

The measured data seems to experience a constant drift after approximately 20 hour. Let’s estimate this drift.

The mean drift is approximately 60.9 [nm/hour] or 1.0 [nm/min]

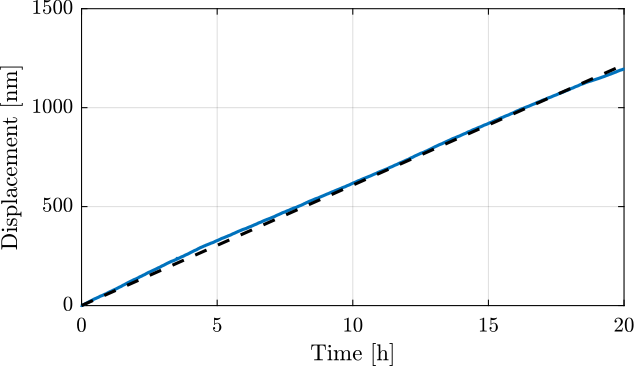

Comparison between the data and the linear fit is shown in Figure 8.

Figure 8: Measured drift and linear fit

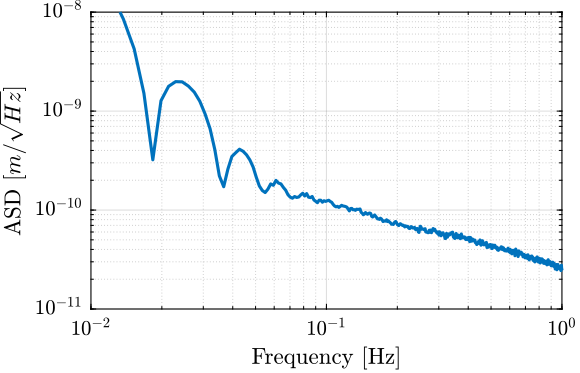

Let’s now estimate the Power Spectral Density of the measured displacement. The obtained low frequency ASD is shown in Figure 9.

Figure 9: Amplitude Spectral density of the measured displacement

3.3 Time Domain signals

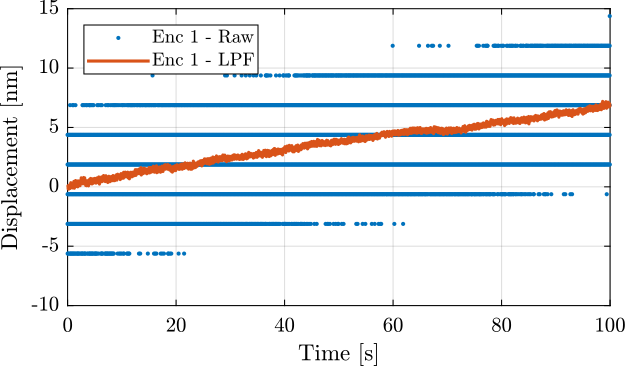

Then, and for all the 7 encoders, we record the measured motion during 100s with a sampling frequency of 20kHz.

The raw measured data as well as the low pass filtered data (using a first order low pass filter with a cut-off at 10Hz) are shown in Figure 10.

Figure 10: Time domain measurement (raw data and low pass filtered data with first order 10Hz LPF)

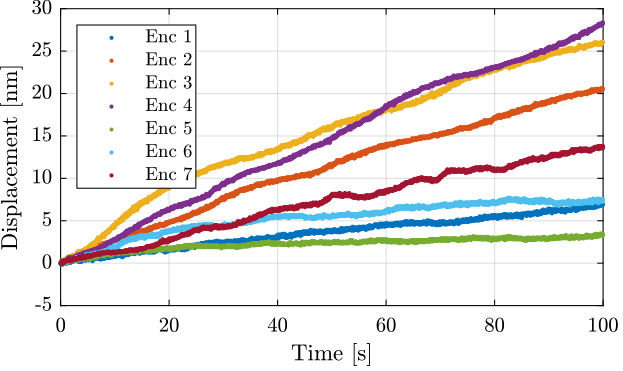

The time domain data for all the encoders are compared in Figure 11.

We can see some drifts that are in the order of few nm to 20nm per minute. As shown in Section 3.2, these drifts should diminish over time down to 1nm/min.

Figure 11: Comparison of the time domain measurement

3.4 Noise Spectral Density

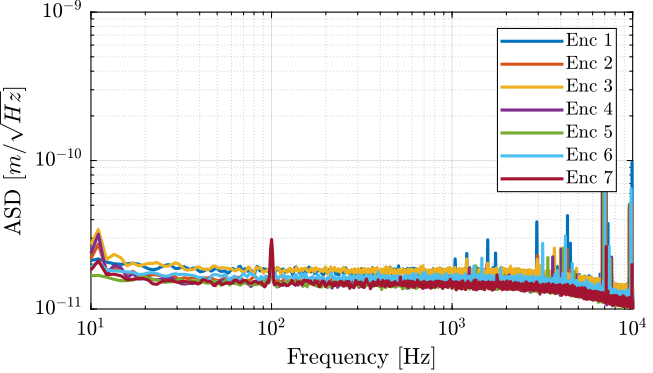

The amplitude spectral densities for all the encoder are computed and shown in Figure 12.

Figure 12: Amplitude Spectral Density of the measured signal

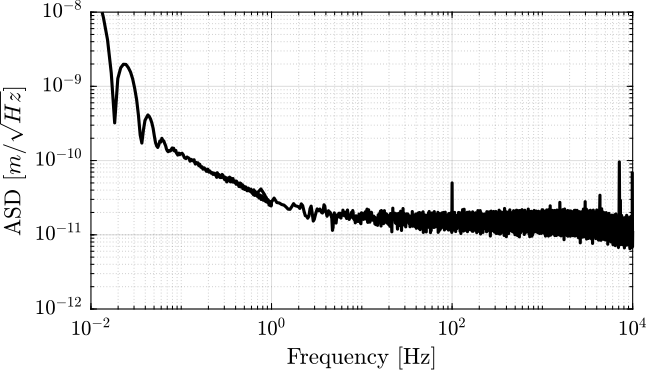

We can combine these measurements with the low frequency noise computed in Section 3.2. The obtained ASD is shown in Figure 13.

Figure 13: Combined low frequency and high frequency noise measurements

3.5 Noise Model

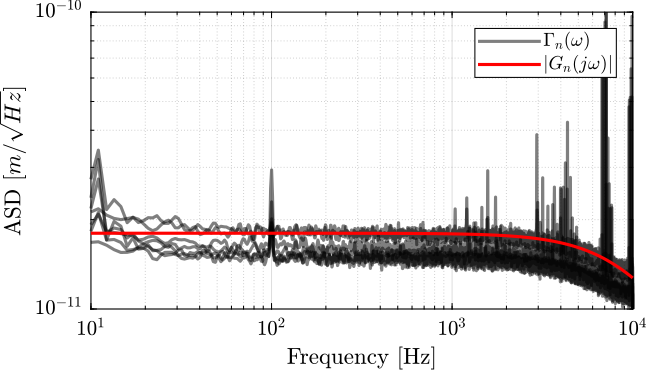

Let’s create a transfer function that approximate the measured noise of the encoder.

Gn_e = 1.8e-11/(1 + s/2/pi/1e4);

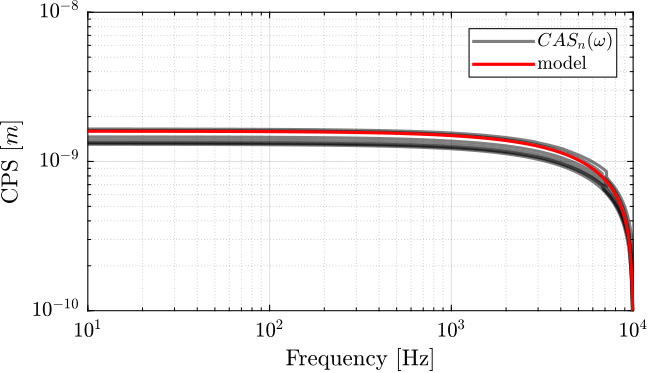

The amplitude of the transfer function and the measured ASD are shown in Figure 14.

Figure 14: Measured ASD of the noise and modeled one

The cumulative amplitude spectrum is now computed and shown in Figure 15.

We can see that the Root Mean Square value of the measurement noise is \(\approx 1.6 \, nm\) as advertise in the datasheet.

Figure 15: Meassured CAS of the noise and modeled one

4 Linearity Measurement

4.1 Test Bench

In order to measure the linearity, we have to compare the measured displacement with a reference sensor with a known linearity. An interferometer or capacitive sensor should work fine. An actuator should also be there so impose a displacement.

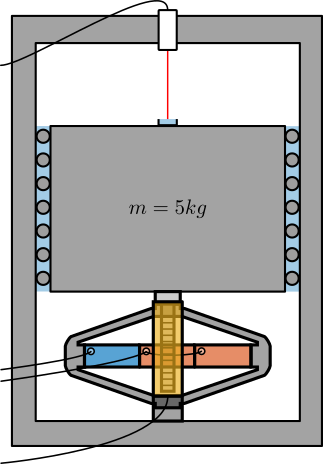

One idea is to use the test-bench shown in Figure 16.

The APA300ML is used to excite the mass in a broad bandwidth. The motion is measured at the same time by the Vionic Encoder and by an interferometer (most likely an Attocube).

As the interferometer has a very large bandwidth, we should be able to estimate the bandwidth of the encoder if it is less than the Nyquist frequency that can be around 10kHz.

Figure 16: Schematic of the test bench