Spindle Analysis

Table of Contents

- 1. Notes

- 2. Data Processing

- 3. Time Domain Data

- 4. Model of the spindle

- 4.1. Schematic of the model

- 4.2. Parameters

- 4.3. Compute Mass and Stiffness Matrices

- 4.4. Compute resonance frequencies

- 4.5. From model_damping compute the Damping Matrix

- 4.6. Define inputs, outputs and state names

- 4.7. Define A, B and C matrices

- 4.8. Generate the State Space Model

- 4.9. Bode Plot

- 4.10. Save the model

- 5. Frequency Domain Data

- 5.1. Load the processed data and the model

- 5.2. Compute the PSD

- 5.3. Plot the computed PSD

- 5.4. Compute the response of the model

- 5.5. Plot the PSD of the Force using the model

- 5.6. Estimated Shape of the PSD of the force

- 5.7. PSD in [N]

- 5.8. PSD in [m]

- 5.9. Compute the resulting RMS value [m]

- 5.10. Compute the resulting RMS value [m]

- 6. Functions

The report made by the PEL is accessible here.

1 Notes

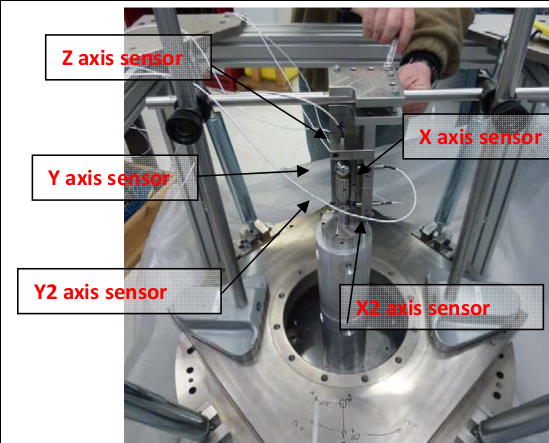

Figure 1: Measurement setup at the PEL lab

| Date | 2017-04-25 |

| Location | PEL Lab |

The goal is to estimate all the error motions induced by the Spindle

2 Data Processing

All the files (data and Matlab scripts) are accessible here.

2.1 Load Measurement Data

spindle_1rpm_table = readtable('./mat/10turns_1rpm_icepap.txt'); spindle_60rpm_table = readtable('./mat/10turns_60rpm_IcepapFIR.txt');

spindle_1rpm_table(1, :)

spindle_1rpm = table2array(spindle_1rpm_table); spindle_60rpm = table2array(spindle_60rpm_table);

2.2 Convert Signals from [deg] to [sec]

speed_1rpm = 360/60; % [deg/sec] spindle_1rpm(:, 1) = spindle_1rpm(:, 2)/speed_1rpm; % From position [deg] to time [s] speed_60rpm = 360/1; % [deg/sec] spindle_60rpm(:, 1) = spindle_60rpm(:, 2)/speed_60rpm; % From position [deg] to time [s]

2.3 Convert Signals

% scaling = 1/80000; % 80 mV/um scaling = 1e-6; % [um] to [m] spindle_1rpm(:, 3:end) = scaling*spindle_1rpm(:, 3:end); % [V] to [m] spindle_1rpm(:, 3:end) = spindle_1rpm(:, 3:end)-mean(spindle_1rpm(:, 3:end)); % Remove mean spindle_60rpm(:, 3:end) = scaling*spindle_60rpm(:, 3:end); % [V] to [m] spindle_60rpm(:, 3:end) = spindle_60rpm(:, 3:end)-mean(spindle_60rpm(:, 3:end)); % Remove mean

2.4 Ts and Fs for both measurements

Ts_1rpm = spindle_1rpm(end, 1)/(length(spindle_1rpm(:, 1))-1); Fs_1rpm = 1/Ts_1rpm; Ts_60rpm = spindle_60rpm(end, 1)/(length(spindle_60rpm(:, 1))-1); Fs_60rpm = 1/Ts_60rpm;

2.5 Find Noise of the ADC [\(\frac{m}{\sqrt{Hz}}\)]

data = spindle_1rpm(:, 5); dV_1rpm = min(abs(data(1) - data(data ~= data(1)))); noise_1rpm = dV_1rpm/sqrt(12*Fs_1rpm/2); data = spindle_60rpm(:, 5); dV_60rpm = min(abs(data(50) - data(data ~= data(50)))); noise_60rpm = dV_60rpm/sqrt(12*Fs_60rpm/2);

2.6 Save all the data under spindle struct

spindle.rpm1.time = spindle_1rpm(:, 1); spindle.rpm1.deg = spindle_1rpm(:, 2); spindle.rpm1.Ts = Ts_1rpm; spindle.rpm1.Fs = 1/Ts_1rpm; spindle.rpm1.x = spindle_1rpm(:, 3); spindle.rpm1.y = spindle_1rpm(:, 4); spindle.rpm1.z = spindle_1rpm(:, 5); spindle.rpm1.adcn = noise_1rpm; spindle.rpm60.time = spindle_60rpm(:, 1); spindle.rpm60.deg = spindle_60rpm(:, 2); spindle.rpm60.Ts = Ts_60rpm; spindle.rpm60.Fs = 1/Ts_60rpm; spindle.rpm60.x = spindle_60rpm(:, 3); spindle.rpm60.y = spindle_60rpm(:, 4); spindle.rpm60.z = spindle_60rpm(:, 5); spindle.rpm60.adcn = noise_60rpm;

2.7 Compute Asynchronous data

for direction = {'x', 'y', 'z'} spindle.rpm1.([direction{1}, 'async']) = getAsynchronousError(spindle.rpm1.(direction{1}), 10); spindle.rpm60.([direction{1}, 'async']) = getAsynchronousError(spindle.rpm60.(direction{1}), 10); end

2.8 Save data

save('./mat/spindle_data.mat', 'spindle');

3 Time Domain Data

All the files (data and Matlab scripts) are accessible here.

3.1 Load the processed data

load('./mat/spindle_data.mat', 'spindle');

3.2 Plot X-Y-Z position with respect to Time - 1rpm

figure; hold on; plot(spindle.rpm1.time, spindle.rpm1.x); plot(spindle.rpm1.time, spindle.rpm1.y); plot(spindle.rpm1.time, spindle.rpm1.z); hold off; xlabel('Time [s]'); ylabel('Amplitude [m]'); legend({'tx - 1rpm', 'ty - 1rpm', 'tz - 1rpm'});

Figure 2: Raw time domain translation - 1rpm

3.3 Plot X-Y-Z position with respect to Time - 60rpm

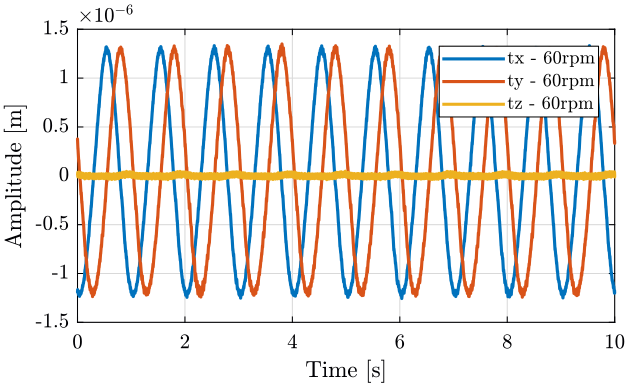

The measurements for the spindle turning at 60rpm are shown figure 3.

figure; hold on; plot(spindle.rpm60.time, spindle.rpm60.x); plot(spindle.rpm60.time, spindle.rpm60.y); plot(spindle.rpm60.time, spindle.rpm60.z); hold off; xlabel('Time [s]'); ylabel('Amplitude [m]'); legend({'tx - 60rpm', 'ty - 60rpm', 'tz - 60rpm'});

Figure 3: Raw time domain translation - 60rpm

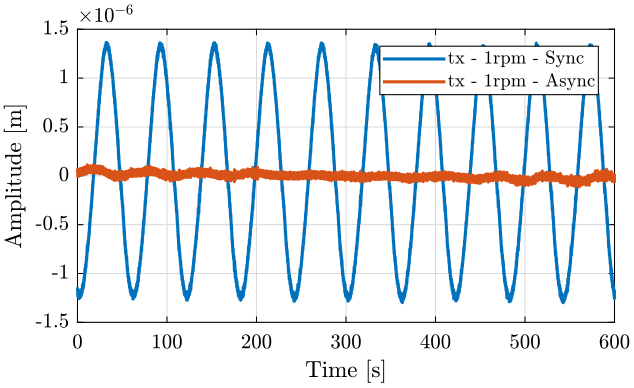

3.4 Plot Synchronous and Asynchronous - 1rpm

figure; hold on; plot(spindle.rpm1.time, spindle.rpm1.x); plot(spindle.rpm1.time, spindle.rpm1.xasync); hold off; xlabel('Time [s]'); ylabel('Amplitude [m]'); legend({'tx - 1rpm - Sync', 'tx - 1rpm - Async'});

Figure 4: Comparison of the synchronous and asynchronous displacements - 1rpm

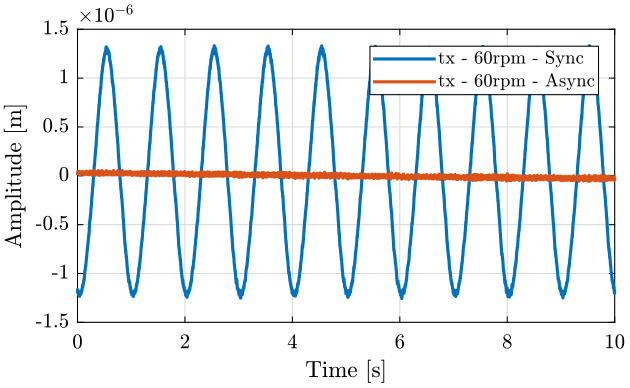

3.5 Plot Synchronous and Asynchronous - 60rpm

The data is split into its Synchronous and Asynchronous part (figure 5). We then use the Asynchronous part for the analysis in the following sections as we suppose that we can deal with the synchronous part with feedforward control.

figure; hold on; plot(spindle.rpm60.time, spindle.rpm60.x); plot(spindle.rpm60.time, spindle.rpm60.xasync); hold off; xlabel('Time [s]'); ylabel('Amplitude [m]'); legend({'tx - 60rpm - Sync', 'tx - 60rpm - Async'});

Figure 5: Comparison of the synchronous and asynchronous displacements - 60rpm

3.6 Plot X against Y

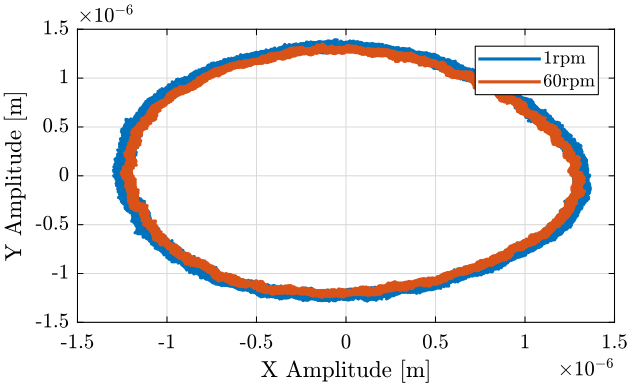

figure; hold on; plot(spindle.rpm1.x, spindle.rpm1.y); plot(spindle.rpm60.x, spindle.rpm60.y); hold off; xlabel('X Amplitude [m]'); ylabel('Y Amplitude [m]'); legend({'1rpm', '60rpm'});

Figure 6: Synchronous x-y displacement

3.7 Plot X against Y - Asynchronous

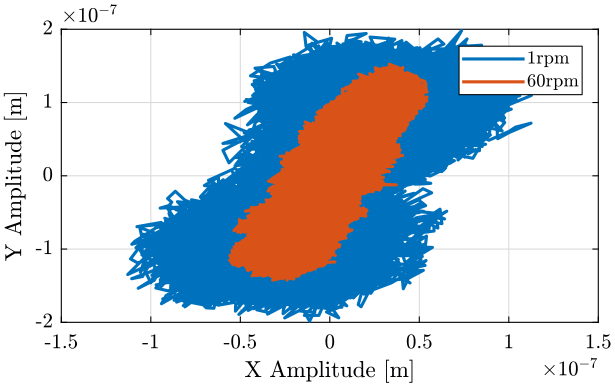

figure; hold on; plot(spindle.rpm1.xasync, spindle.rpm1.yasync); plot(spindle.rpm60.xasync, spindle.rpm60.yasync); hold off; xlabel('X Amplitude [m]'); ylabel('Y Amplitude [m]'); legend({'1rpm', '60rpm'});

Figure 7: Asynchronous x-y displacement

4 Model of the spindle

All the files (data and Matlab scripts) are accessible here.

4.1 Schematic of the model

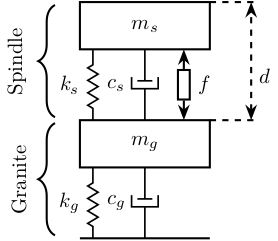

The model of the spindle used is shown figure 8.

\(f\) is the perturbation force of the spindle and \(d\) is the measured displacement.

Figure 8: Model of the Spindle

4.2 Parameters

mg = 3000; % Mass of granite [kg] ms = 50; % Mass of Spindle [kg] kg = 1e8; % Stiffness of granite [N/m] ks = 5e7; % Stiffness of spindle [N/m]

4.3 Compute Mass and Stiffness Matrices

Mm = diag([ms, mg]); Km = diag([ks, ks+kg]) - diag(ks, -1) - diag(ks, 1);

4.4 Compute resonance frequencies

A = [zeros(size(Mm)) eye(size(Mm)) ; -Mm\Km zeros(size(Mm))]; eigA = imag(eigs(A))/2/pi; eigA = eigA(eigA>0); eigA = eigA(1:2);

4.5 From model_damping compute the Damping Matrix

modal_damping = 1e-5; ab = [0.5*eigA(1) 0.5/eigA(1) ; 0.5*eigA(2) 0.5/eigA(2)]\[modal_damping ; modal_damping]; Cm = ab(1)*Mm +ab(2)*Km;

4.6 Define inputs, outputs and state names

StateName = {...

'xs', ... % Displacement of Spindle [m]

'xg', ... % Displacement of Granite [m]

'vs', ... % Velocity of Spindle [m]

'vg', ... % Velocity of Granite [m]

};

StateUnit = {'m', 'm', 'm/s', 'm/s'};

InputName = {...

'f' ... % Spindle Force [N]

};

InputUnit = {'N'};

OutputName = {...

'd' ... % Displacement [m]

};

OutputUnit = {'m'};

4.7 Define A, B and C matrices

% A Matrix A = [zeros(size(Mm)) eye(size(Mm)) ; ... -Mm\Km -Mm\Cm]; % B Matrix B_low = zeros(length(StateName), length(InputName)); B_low(strcmp(StateName,'vs'), strcmp(InputName,'f')) = 1; B_low(strcmp(StateName,'vg'), strcmp(InputName,'f')) = -1; B = blkdiag(zeros(length(StateName)/2), pinv(Mm))*B_low; % C Matrix C = zeros(length(OutputName), length(StateName)); C(strcmp(OutputName,'d'), strcmp(StateName,'xs')) = 1; C(strcmp(OutputName,'d'), strcmp(StateName,'xg')) = -1; % D Matrix D = zeros(length(OutputName), length(InputName));

4.8 Generate the State Space Model

sys = ss(A, B, C, D); sys.StateName = StateName; sys.StateUnit = StateUnit; sys.InputName = InputName; sys.InputUnit = InputUnit; sys.OutputName = OutputName; sys.OutputUnit = OutputUnit;

4.9 Bode Plot

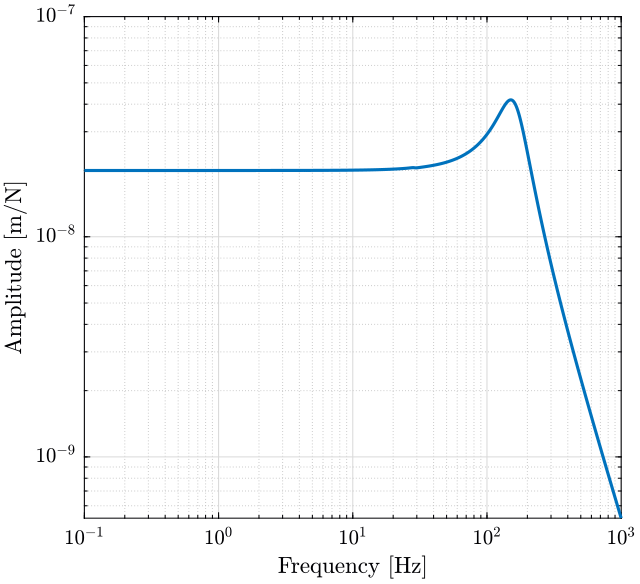

The transfer function from a disturbance force \(f\) to the measured displacement \(d\) is shown figure 9.

freqs = logspace(-1, 3, 1000); figure; plot(freqs, abs(squeeze(freqresp(sys('d', 'f'), freqs, 'Hz')))); set(gca, 'XScale', 'log'); set(gca, 'YScale', 'log'); xlabel('Frequency [Hz]'); ylabel('Amplitude [m/N]');

Figure 9: Bode plot of the transfer function from \(f\) to \(d\)

4.10 Save the model

save('./mat/spindle_model.mat', 'sys');

5 Frequency Domain Data

All the files (data and Matlab scripts) are accessible here.

5.1 Load the processed data and the model

load('./mat/spindle_data.mat', 'spindle'); load('./mat/spindle_model.mat', 'sys');

5.2 Compute the PSD

n_av = 4; % Number of average [pxx_1rpm, f_1rpm] = pwelch(spindle.rpm1.xasync, hanning(ceil(length(spindle.rpm1.xasync)/n_av)), [], [], spindle.rpm1.Fs); [pyy_1rpm, ~] = pwelch(spindle.rpm1.yasync, hanning(ceil(length(spindle.rpm1.yasync)/n_av)), [], [], spindle.rpm1.Fs); [pzz_1rpm, ~] = pwelch(spindle.rpm1.zasync, hanning(ceil(length(spindle.rpm1.zasync)/n_av)), [], [], spindle.rpm1.Fs); [pxx_60rpm, f_60rpm] = pwelch(spindle.rpm60.xasync, hanning(ceil(length(spindle.rpm60.xasync)/n_av)), [], [], spindle.rpm60.Fs); [pyy_60rpm, ~] = pwelch(spindle.rpm60.yasync, hanning(ceil(length(spindle.rpm60.yasync)/n_av)), [], [], spindle.rpm60.Fs); [pzz_60rpm, ~] = pwelch(spindle.rpm60.zasync, hanning(ceil(length(spindle.rpm60.zasync)/n_av)), [], [], spindle.rpm60.Fs);

5.3 Plot the computed PSD

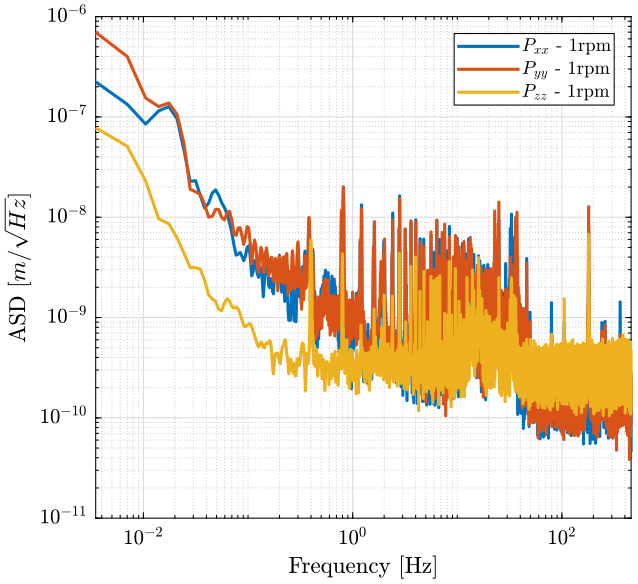

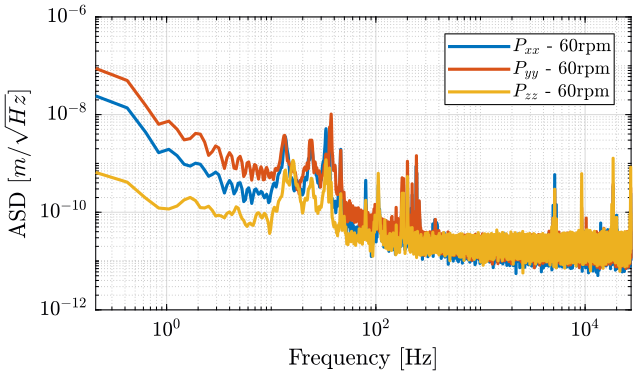

The Amplitude Spectral Densities of the displacement of the spindle for the \(x\), \(y\) and \(z\) directions are shown figure 11. They correspond to the Asynchronous part shown figure 5.

figure; hold on; plot(f_1rpm, (pxx_1rpm).^.5, 'DisplayName', '$P_{xx}$ - 1rpm'); plot(f_1rpm, (pyy_1rpm).^.5, 'DisplayName', '$P_{yy}$ - 1rpm'); plot(f_1rpm, (pzz_1rpm).^.5, 'DisplayName', '$P_{zz}$ - 1rpm'); % plot(f_1rpm, spindle.rpm1.adcn*ones(size(f_1rpm)), '--k', 'DisplayName', 'ADC - 1rpm'); hold off; set(gca, 'XScale', 'log'); set(gca, 'YScale', 'log'); xlabel('Frequency [Hz]'); ylabel('ASD [$m/\sqrt{Hz}$]'); legend('Location', 'northeast'); xlim([f_1rpm(2), f_1rpm(end)]);

Figure 10: Power spectral density of the Asynchronous displacement - 1rpm

figure; hold on; plot(f_60rpm, (pxx_60rpm).^.5, 'DisplayName', '$P_{xx}$ - 60rpm'); plot(f_60rpm, (pyy_60rpm).^.5, 'DisplayName', '$P_{yy}$ - 60rpm'); plot(f_60rpm, (pzz_60rpm).^.5, 'DisplayName', '$P_{zz}$ - 60rpm'); % plot(f_60rpm, spindle.rpm60.adcn*ones(size(f_60rpm)), '--k', 'DisplayName', 'ADC - 60rpm'); hold off; set(gca, 'XScale', 'log'); set(gca, 'YScale', 'log'); xlabel('Frequency [Hz]'); ylabel('ASD [$m/\sqrt{Hz}$]'); legend('Location', 'northeast'); xlim([f_60rpm(2), f_60rpm(end)]);

Figure 11: Power spectral density of the Asynchronous displacement - 60rpm

5.4 Compute the response of the model

Tfd = abs(squeeze(freqresp(sys('d', 'f'), f_60rpm, 'Hz')));

5.5 Plot the PSD of the Force using the model

figure; plot(f_60rpm, (pxx_60rpm.^.5)./Tfd, 'DisplayName', '$P_{xx}$'); set(gca, 'XScale', 'log'); set(gca, 'YScale', 'log'); xlabel('Frequency [Hz]'); ylabel('ASD [$N/\sqrt{Hz}$]'); xlim([f_60rpm(2), f_60rpm(end)]);

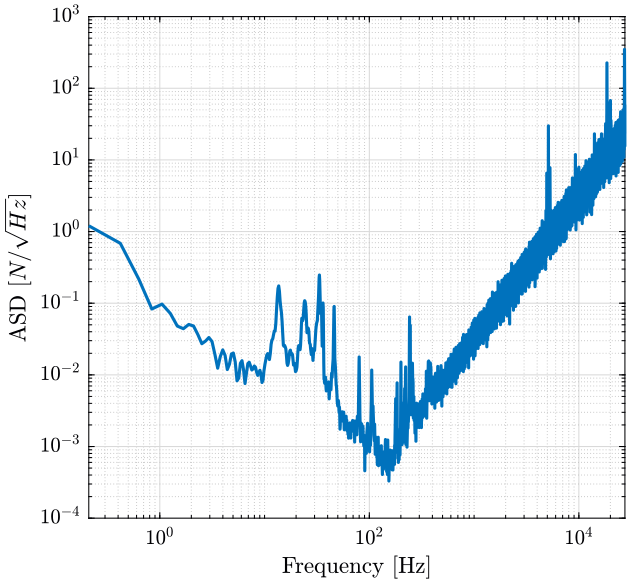

Figure 12: Power spectral density of the force - 60rpm

5.6 Estimated Shape of the PSD of the force

s = tf('s'); Wd_simple = 1e-8/(1+s/2/pi/0.5)/(1+s/2/pi/100); Wf_simple = Wd_simple/tf(sys('d', 'f')); TWf_simple = abs(squeeze(freqresp(Wf_simple, f_60rpm, 'Hz'))); % Wf = 0.48902*(s+327.9)*(s^2 + 109.6*s + 1.687e04)/((s^2 + 30.59*s + 8541)*(s^2 + 29.11*s + 3.268e04)); % Wf = 0.15788*(s+418.6)*(s+1697)^2*(s^2 + 124.3*s + 2.529e04)*(s^2 + 681.3*s + 9.018e05)/((s^2 + 23.03*s + 8916)*(s^2 + 33.85*s + 6.559e04)*(s^2 + 71.43*s + 4.283e05)*(s^2 + 40.64*s + 1.789e06)); Wf = (s+1697)^2*(s^2 + 114.5*s + 2.278e04)*(s^2 + 205.1*s + 1.627e05)*(s^2 + 285.8*s + 8.624e05)*(s+100)/((s+0.5)*3012*(s^2 + 23.03*s + 8916)*(s^2 + 17.07*s + 4.798e04)*(s^2 + 41.17*s + 4.347e05)*(s^2 + 78.99*s + 1.789e06)); TWf = abs(squeeze(freqresp(Wf, f_60rpm, 'Hz')));

5.7 PSD in [N]

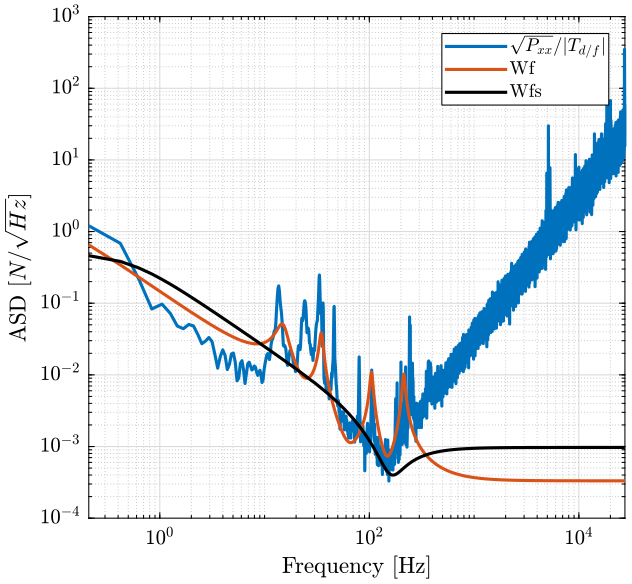

Above \(200Hz\), the Amplitude Spectral Density seems dominated by noise coming from the electronics (charge amplifier, ADC, …). So we don’t know what is the frequency content of the force above that frequency. However, we assume that \(P_{xx}\) is decreasing with \(1/f\) as it seems so be the case below \(100Hz\) (figure 11).

We then fit the PSD of the displacement with a transfer function (figure 14).

figure; hold on; plot(f_60rpm, (pxx_60rpm.^.5)./Tfd, 'DisplayName', '$\sqrt{P_{xx}}/|T_{d/f}|$'); plot(f_60rpm, TWf, 'DisplayName', 'Wf'); plot(f_60rpm, TWf_simple, '-k', 'DisplayName', 'Wfs'); set(gca, 'XScale', 'log'); set(gca, 'YScale', 'log'); xlabel('Frequency [Hz]'); ylabel('ASD [$N/\sqrt{Hz}$]'); xlim([f_60rpm(2), f_60rpm(end)]); legend('Location', 'northeast');

Figure 13: Power spectral density of the force - 60rpm

5.8 PSD in [m]

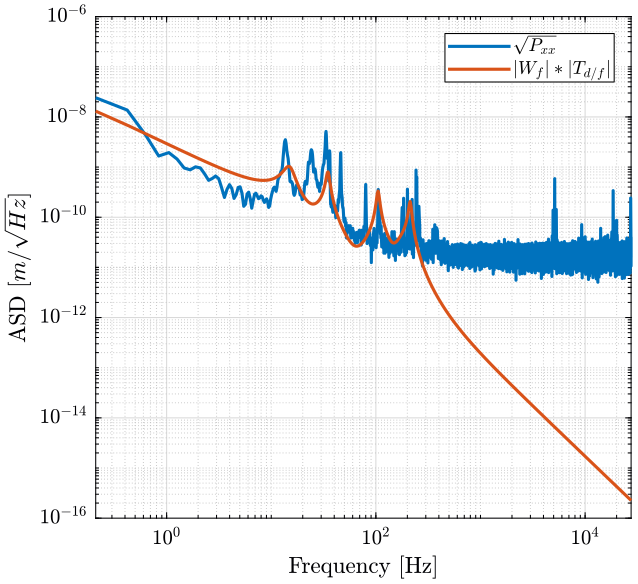

To obtain the PSD of the force \(f\) that induce such displacement, we use the following formula: \[ \sqrt{PSD(d)} = |T_{d/f}| \sqrt{PSD(f)} \]

And so we have: \[ \sqrt{PSD(f)} = |T_{d/f}|^{-1} \sqrt{PSD(d)} \]

The obtain Power Spectral Density of the force is displayed figure 13.

figure; hold on; plot(f_60rpm, pxx_60rpm.^.5, 'DisplayName', '$\sqrt{P_{xx}}$'); plot(f_60rpm, TWf.*Tfd, 'DisplayName', '$|W_f|*|T_{d/f}|$'); set(gca, 'XScale', 'log'); set(gca, 'YScale', 'log'); xlabel('Frequency [Hz]'); ylabel('ASD [$m/\sqrt{Hz}$]'); xlim([f_60rpm(2), f_60rpm(end)]); legend('Location', 'northeast');

Figure 14: Comparison of the power spectral density of the measured displacement and of the model

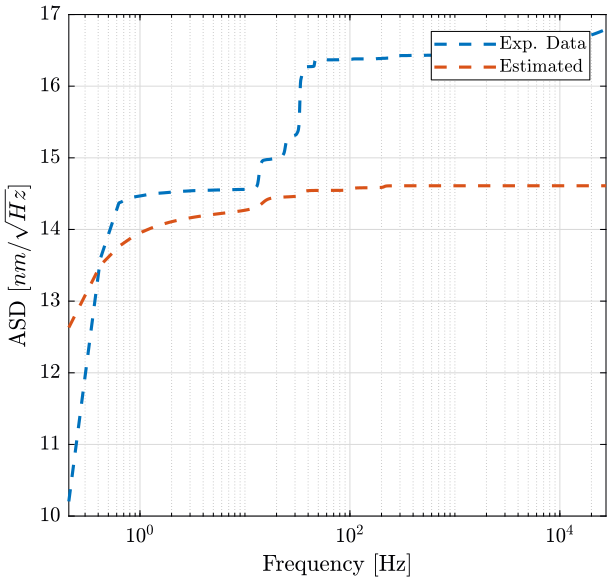

5.9 Compute the resulting RMS value [m]

figure; hold on; plot(f_60rpm, 1e9*cumtrapz(f_60rpm, (pxx_60rpm)).^.5, '--', 'DisplayName', 'Exp. Data'); plot(f_60rpm, 1e9*cumtrapz(f_60rpm, ((TWf.*Tfd).^2)).^.5, '--', 'DisplayName', 'Estimated'); hold off; set(gca, 'XScale', 'log'); xlabel('Frequency [Hz]'); ylabel('CPS [$nm$ rms]'); xlim([f_60rpm(2), f_60rpm(end)]); legend('Location', 'southeast');

Figure 15: Cumulative Power Spectrum - 60rpm

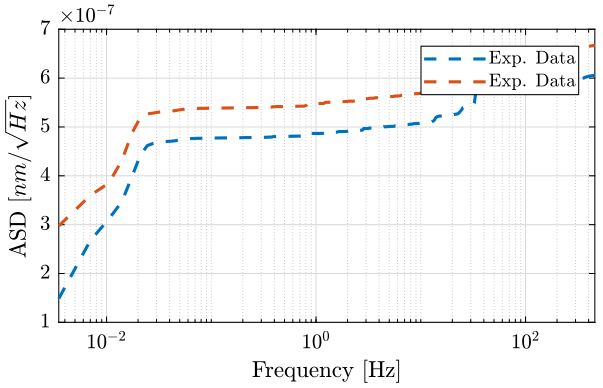

5.10 Compute the resulting RMS value [m]

figure; hold on; plot(f_1rpm, 1e9*cumtrapz(f_1rpm, (pxx_1rpm)), '--', 'DisplayName', 'Exp. Data'); plot(f_1rpm, 1e9*(f_1rpm(end)-f_1rpm(1))/(length(f_1rpm)-1)*cumsum(pxx_1rpm), '--', 'DisplayName', 'Exp. Data'); hold off; set(gca, 'XScale', 'log'); xlabel('Frequency [Hz]'); ylabel('CPS [$nm$ rms]'); xlim([f_1rpm(2), f_1rpm(end)]); legend('Location', 'southeast');

Figure 16: Cumulative Power Spectrum - 1rpm

6 Functions

6.1 getAsynchronousError

This Matlab function is accessible here.

function [Wxdec] = getAsynchronousError(data, NbTurn) %% L = length(data); res_per_rev = L/NbTurn; P = 0:(res_per_rev*NbTurn-1); Pos = P' * 360/res_per_rev; % Temperature correction x1 = myfit2(Pos, data); % Convert data to frequency domain and scale accordingly X2 = 2/(res_per_rev*NbTurn)*fft(x1); f2 = (0:L-1)./NbTurn; %upr -> once per revolution %% X2dec = zeros(size(X2)); % Get only the non integer data X2dec(mod(f2(:), 1) ~= 0) = X2(mod(f2(:), 1) ~= 0); Wxdec = real((res_per_rev*NbTurn)/2 * ifft(X2dec)); %% function Y = myfit2(x,y) A = [x ones(size(x))]\y; a = A(1); b = A(2); Y = y - (a*x + b); end end